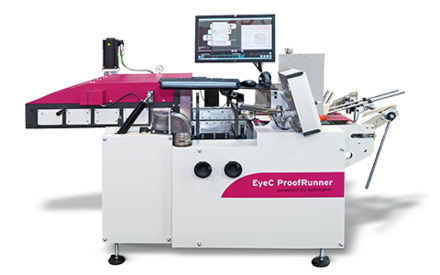

With the EyeC ProofRunner Carton Folder Gluer installed on a pre-feeder module, combine the latest print inspection technology with your existing folder gluer. The flexible and movable pre-feeder unit can easily be connected to any folder gluer to convert it into the perfect inspection solution for folding cartons.

By allowing print shops to take advantage of the latest 100% print inspection technology without replacing their existing machinery, the EyeC ProofRunner Carton Folder Gluer a cost-effective and reliable solution to avoid customer rejects, keep existing customers satisfied, and achieve new business opportunities.

Meet high-quality requirements

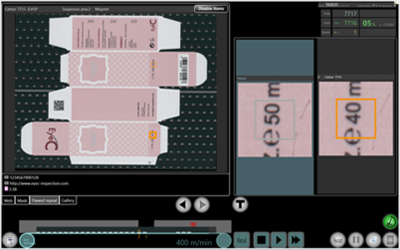

As required for most packaged materials for pharmaceutical, cosmetic, toiletry, and branded products, the EyeC ProofRunner Carton Folder Gluer inspects 100% of the production of folding cartons, and compares it against the signed-off proof (typically a PDF file). The in-line system verifies the entire carton surface, including all flaps. It uses the folder gluer’s existing ejection device to reject any defective item, and provides a full inspection report.

The EyeC ProofRunner Carton Folder Gluer makes it easy to avoid customer rejects and keep existing customers satisfied. By ensuring defect-free deliveries, it provides a key sales argument to differentiate from competition, and opens new business opportunities.

A fast, accurate and flexible solution

The EyeC ProofRunner Carton Folder Gluer allows print shops to increase their print quality, while optimizing existing processes and resources. Compact and easy to connect, the pre-feeder module can be placed in front of any folder gluer.

Thanks to the EyeC ProofRunner Carton Folder Gluer, no additional process or operator is needed to perform a full and accurate print inspection. Moreover, even if operated at a speed of up to 300 m/min (984 ft/min), it detects the relevant defects, so the operator does not have to slow down production or compromise on quality standards.

Increase operator satisfaction

The EyeC ProofRunner Carton Folder Gluer has been designed with ease-of-use in mind. This in-line inspection system is quick to set-up and easy to use. The intuitive interface, available in all major languages, guides the operator, increasing process safety, while simplifying quality controls and enhancing operator satisfaction.

The high performance vacuum belt of the pre-feeder module guarantees safe handling of all cartons as well as their proper alignment. The system is easy to maintain.