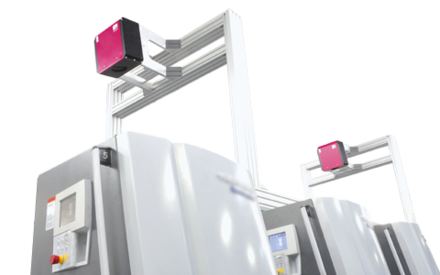

The EyeC ProofRunner Sheetfed is a retrofit module designed to inspect sheets during printing. Available for numerous sheet-fed offset presses (such as the ones from Koenig & Bauer, Manroland Sheetfed and Heidelberg), this in-line system monitors the quality of the entire print job, checks it against the customer proof. In case of defects, it either alerts the operator or triggers a tab to be inserted into the load.

Reduce material waste and production costs

Productivity is the key to facing the increasing competition and improving the bottom line.

Upon finding a repeating problem, this system alerts the press operator right away, so – unlike inspecting downstream – the problem gets resolved immediately thus avoiding waste. Furthermore, this system counts the number of good items produced, thus reducing the amount of overprint necessary to meet the intended job volume. As a result, the EyeC ProofRunner Sheetfed prevents the waste of expensive consumables and valuable machine time.

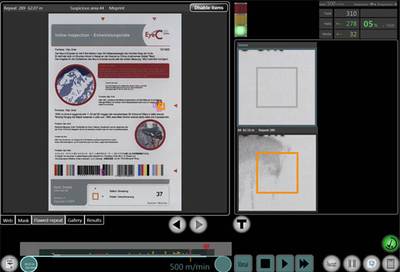

Accurately check the content of 100% of your sheets

The EyeC ProofRunner Sheetfed identifies all typical defects, such as errors in text, color deviations, misregisters, press contamination, hickeys, filled in or missing characters. By performing an initial check against the approved artwork PDF, it provides a reliable content verification in any languages, and prevents job mix-up.

Run at full press speed

Thanks to its easy job set-up, high inspection speed and accurate defects detection, the EyeC ProofRunner Sheetfed offers best-in-class performances. There is no need to slow down production to inspect the job - the system can detect the smallest defects at a maximum press speed of up to 20,000 sheets per hour.

Increase operator’s satisfaction

The EyeC ProofRunner Sheetfed simplifies quality checks and enhances operator satisfaction. The inspection system only alerts the operator in case of significant deviations, reducing potential eye strain and fatigue. The clear presentation of deviations and key statistical information – such as the defect heatmap - help the operator to understand the location and origin of printing defects easily. The full inspection report that is produced at the end of each job automatically, offers managers a perfect tracking, analysis and communication support.