The EyeC Workflow Integration incorporates our pre-press inspection technology into workflow systems such as Esko's Automation Engine. It helps you boost both security and efficiency at pre-press.

For modern workflow solutions

Designed for workflow systems such as Esko's Automation Engine, the EyeC Workflow Integration incorporates our best-in-class pre-press inspection solution — the EyeCProofiler Graphic — into your pre-press workflow, forming an integrated, standardized and automated quality control procedure.

Integrated quality control

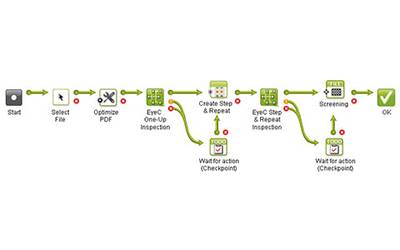

The EyeC Workflow Integration boosts both security and efficiency. It allows you to create as many inspection procedures as needed. The software can compare your files against the ones of your customers, one-up against step-and-repeat files or different versions of a file. The integration triggers inspection procedures automatically, retrieving job data, files and inspection parameters from your workflow system. Problems will get caught right away before any work is wasted on subsequent steps.

Automated pre-press inspection

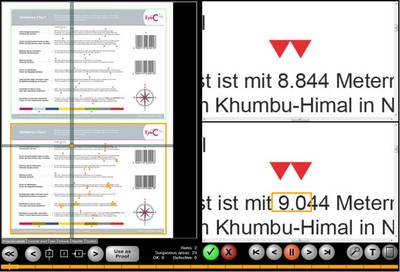

Choose the level of automation that best fits your needs. Opt for semi-automatic to manually approve discrepancies in the EyeC Proofiler Graphic user interface. During the initial pre-press work, use it to make sure all intentional changes are accounted for and nothing has been modified inadvertently. Or opt for full automation to let the workflow inspect and release your files automatically if they match the approved artwork. For instance, before plate making.

Accurate and complete PDF check

The EyeC Proofiler Graphic verifies the entire content of your pre-press files against the approved artwork. Text, graphics, Braille, 1D and 2D codes are checked graphically in a single inspection cycle. Inspection results are reported back to the workflow system and deviations brought to the operator's attention.