100% Print Inspection

The EyeC ProofRunner works with pretty much any type of printed materials including cartons, labels, flexible packaging, and leaflets performing meaningful inspection of the entire surface of every single item:

- on a sheet-fed offset press running at up to 20,000 sheets per hour

- on a web-fed press or on a rewinder running at up to 1,968 ft/min (600 m/min)

- on a folder gluer running at up to 100,000 cartons per hour

Our ProofRunner systems are directly installed on a press or finishing machine and inspect the entire print job in real time. On a printing press, this allows the operator to implement corrective action immediately, improving overall quality and preventing unnecessary waste. On a finishing machine, defective items can be ejected ensuring 100% defect free delivery, preventing costly rejects, and contributing to customer satisfaction.

Easy to Use

The EyeC ProofRunner is quick to set-up and easy to use. The intuitive interface guides the operator, increasing process safety, while simplifying quality controls and enhancing the operator’s satisfaction. A full inspection report is produced at the end of each job automatically, offering managers perfect tracking, analysis and communication support.

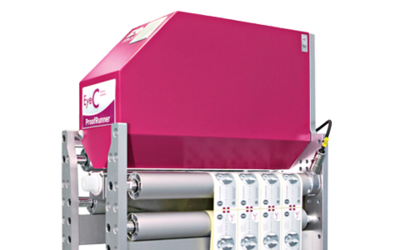

EyeC ProofRunner Web

Ensure the delivery of quality compliant labels, leaflets or flexible packaging

The EyeC ProofRunner Web series is a complete range of in-line inspection systems for label, leaflet, foil and flexible packaging printing. Suitable inspecting any type of narrow- to mid-web products - including transparent or metalized labels, inserts, outserts, patient information leaflets, flexible material or film -, they perform a 100% print inspection, and provide an efficient job mix-up…

EyeC ProofRunner Carton Folder Gluer

Easily add print inspection to your folder gluer and check 100% of your material before delivery

With the EyeC ProofRunner Carton Folder Gluer installed on a pre-feeder module, combine the latest print inspection technology with your existing folder gluer. The flexible and movable pre-feeder unit can easily be connected to any folder gluer to convert it into the perfect inspection solution for folding cartons.

By allowing print shops to take advantage of the latest 100% print inspection…

EyeC ProofRunner Carton Sorter

Ensure the delivery of high-quality, error-free folding cartons

The EyeC ProofRunner Carton Sorter is an in-line inspection system that ensures the delivery of high-quality, error-free folding cartons. Installed on a sorting unit, it checks the quality of 100% of the folding boxes before their shipment to customers.

Capable of checking the output from several machines, the EyeC ProofRunner Carton Sorter offers a flexible and reliable solution to avoid…

EyeC ProofRunner Sheetfed

Improve your print quality while reducing production time and costs

The EyeC ProofRunner Sheetfed is a retrofit module designed to inspect sheets during printing. Available for numerous sheet-fed offset presses (such as the ones from Koenig & Bauer, Manroland Sheetfed and Heidelberg), this in-line system monitors the quality of the entire print job, checks it against the customer proof. In case of defects, it either alerts the operator or triggers a tab to be…

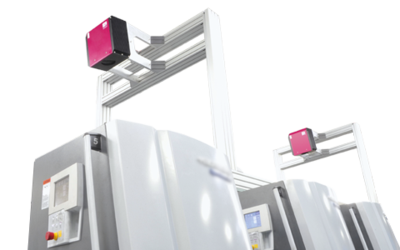

EyeC Quality Link

Link your press and rewinder for maximum productivity

The EyeC Quality Link connects your press and rewinder for total quality control at maximum productivity. Thanks to the EyeC Quality Link, reduce waste by monitoring your print quality on the press, improve safety by evaluating the quality of each printed roll on a work station, and speed up the removal of faulty material on the rewinder.