Thanks to the EyeC Proofiler the print quality check of packaging at Pierre Fabre Dermo-Cosmétique no longer takes 45 minutes but only 5. As the third biggest French pharma laboratory, Pierre Fabre, is a pioneer in the field of dermo-cosmetics. More than a half of its turnover is generated in this branch; that was 1,148 million euros in 2014 (62% thereof obtained on an international level). Their product portfolio includes seven brands: besides the most well-known, Avène, it covers the brands Klorane, Ducray, A-Derma, René Furterer, Galénic and Elancyl.

Cosmetics are produced under the same guidelines as medication

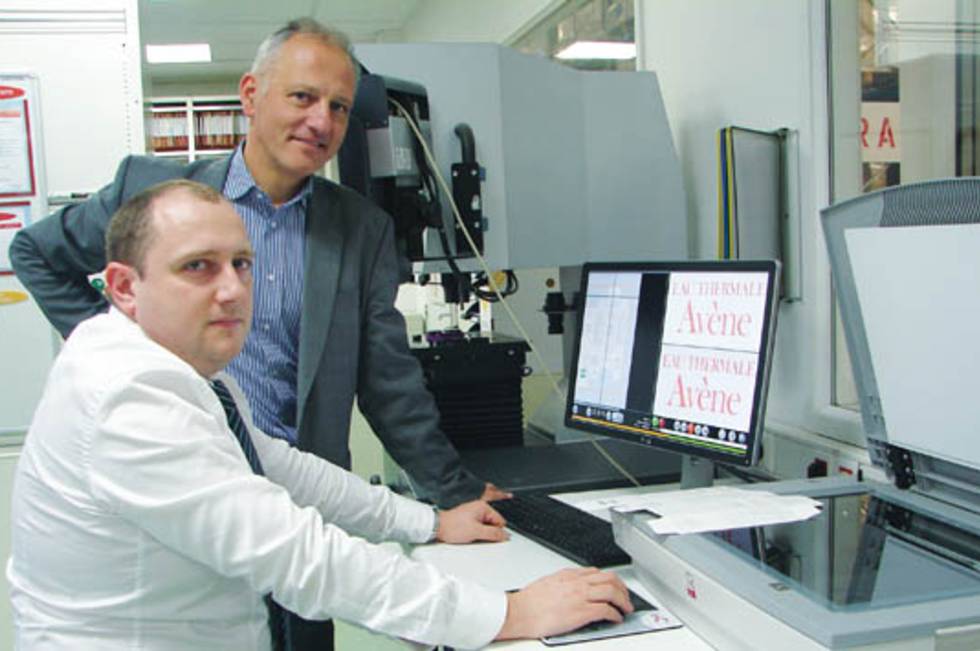

Pierre Fabre’s dermo-cosmetic products are manufactured in production sites in France which also have been validated for the production of medication. Comprehensive quality controls take top priority here. This also applies to the central warehouse in Castres, a few kilometers from Soual where more than 4000 packaged units are stored, controlled, and then released in an area of 20000m2. Nicolas Mouquot, head of the quality control laboratory, is responsible for the quality inspection on site. He is supported by a team of 10 inspectors who check every single aspect of the packaging: cleanliness, functionality, as well as texts, logos and graphics. Not even a year ago, texts and graphics were still checked manually – a complex, tedious and often exhausting task.

Weak points of manual checking

“The risk of checking manually”, says Nicolas Mouquot, “is that the technician may correct certain defects out of habit.” The only way to prevent this unconscious correction is maximum concentration. “That is why our technicians must not check the same type of packaging twice.” In addition, certain defects are nearly invisible to the human eye. “Some abbreviations differ only in one single number or letter. If a product contains a defective token corresponding to another actually existing component, it can be very hard to tell.” Safety notes are a particularly sensitive issue. “This is where information changes the most. The risk of making a layout error is high.” Unfortunately it is not always easy to recognize that a modified text has suddenly disappeared behind a graphic or a barcode.

Faster reaction required

Besides these complex quality requirements, the controllers have to work increasingly faster. “Within four years the production volume has increased by 30%.” At Pierre Fabre, the controls take place before the products are sent to the factory. Priorities are set according to the production schedule. “A delay during the control stage can lead to standstill of the production lines.” To increase the efficiency and productivity, Nicolas Mouquot searched for an automated print control system. His laboratory tested the highest rated systems on the market: “We designed tests to check the systems for all types of packaging components we need to control: labels, folding cartons, leaflets, aluminum tubes and plastic tubes."

Choosing the automated EyeC Proofiler

After this evaluation, Pierre Fabre chose the EyeC Proofiler 400 Enhanced. This system, equipped with a feature to check Braille and barcodes, allows proofs to be scanned and automatically checked against the corresponding PDF file. After a few seconds the differences appear – prepress defects as well as print defects – and the user only has to evaluate them. The program then provides a comprehensive inspection report. Nicolas Mouquot explains: “Our decisive criteria was the system’s ease-of-use, the rapidity of the control and the accuracy of the results. Another argument in favor of EyeC: “The Proofiler was very quickly ready for use.” The availability of Fabrice Hardouin, the French representative of EyeC, and the simplicity with which he defined the ideal parameter set for Pierre Fabre made the difference.

Ease-of-use and Efficiency

What Nicolas Mouquot and his inspectors appreciate the most: “The ease-of-use of the EyeC Proofiler, the fact that the software is very intuitive.” The efficiency of the Proofiler is also a key advantage of the system. “The inspection of leaflets on thin paper for example works very well with the Proofiler. For other inspection systems the transparency of the texts on the backside causes great difficulties.”

“Just the possibility to avoid the complaint of a defective product already brought to the market makes the investment profitable.” However, it is hard to foresee the number of complaints. “In order to calculate the return on investment we mainly took account of the gain of time and the ergonomics.” With the installation of the EyeC Proofiler, the inspection and confirmation of the print quality of a packaging no longer takes 45 minutes but only 5. By means of the software, the inspection is no longer tedious for employees. “The technicians prefer demanding tasks, such as evaluating the differences, and leave the repetitive, tedious work to the machine."

Gain of time, ease-of-use, and safety

“The Proofiler also provides great safety within quality control – especially when it comes to texts with non-European characters such as Asian or Arabic.”

Finally, the laboratory’s relationship with its suppliers has improved and their communication has become quicker. “Thanks to the comprehensive inspection report, the accuracy of the results becomes very clear. If there are any disagreements in terms of quality with our suppliers we have convincing proof. Before, we had to take a picture, create a document and then circle the problem in order to prove it. Now, sending the inspection report is enough.”

Within one year, the EyeC Proofiler has created more than 1,490 inspection reports and has checked the quality of over 730 different packaging components. Pierre Fabre has increased its productivity and has found a partnership with EyeC that meets its high quality requirements.